YiCai Factory in ZhongShan, GuangDong, China

The factory was established since 2009 and has been focusing on the production and development of sustainable and eco friendly bamboo and wood color cosmetic packaging for more than 14 years.

The factory include cutting workshop, forming workshop, grinding workshop, spraying workshop, assembly workshop, decoration workshop and finished product inspection workshop, etc.

With our professional technology and our full equipped hardware abilities,by our strict quality control system,our products achieve world-class leading quality.

Corner of Factory

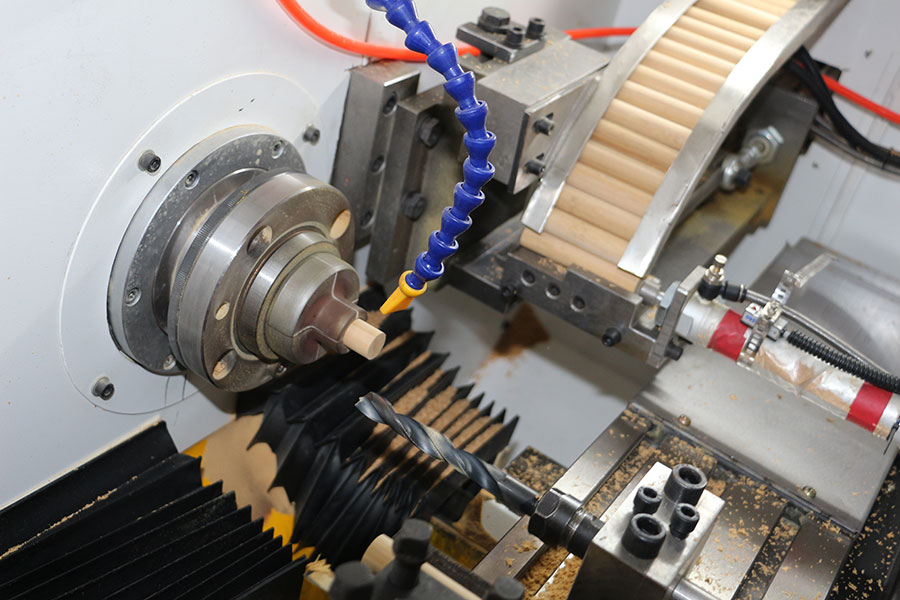

44 sets

of automated production equipment

21,520

square feet covers an area of

5000-10000pcs

Daily production capacity.

Customized Facilities

Each machine is independently customized for a full range of cosmetic packaging to ensure the accuracy of product dimensions, including bamboo lipstick tubes, bamboo balm tubes, bamboo mascara tubes, bamboo lip gloss tubes, bamboo eyeliner tubes, bamboo eye shadow palette, bamboo gift box, bamboo loose powder box, bamboo compact powder palette, bamboo blush palette etc.

Factory Site Overview

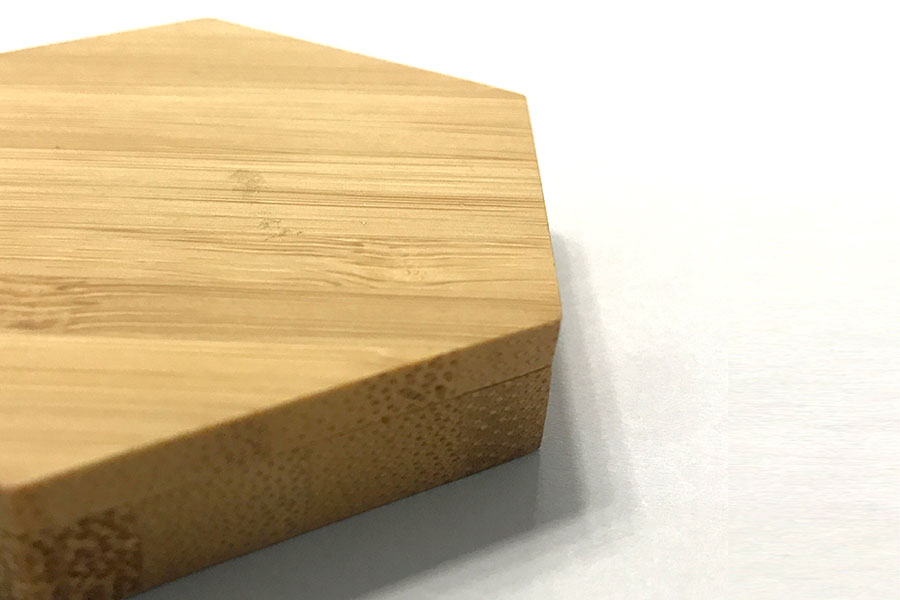

Quality And Technical

Our quality control starts from the selection of raw materials to ensure the bamboo raw materials suitable materials for cosmetics packaging, the raw materials meet the FSC certification, and the accessories used need to pass the EU testing;

Establish online operation specifications, instructions, and online inspections for each processing procedure to ensure the finished products 100% qualified. All around products has strict operation instruction and inspection standards, the factory has professional testing equipment in house, which of the product needs to pass Reach test, and the surface decoration needs to pass the 100 grid test.

For more than ten years, we have achieved zero customer complaints.

Product Accuracy

Due to the particularity of bamboo raw materials, the control of accuracy is a difficult problem. After years of research, experience and lessons on bamboo packaging products, we have repeatedly tested, improved, and developed suitable production machines, which are suitable for different series of products. Different customized production equipment, the tolerance of each process is controlled within 0.005mm, and the error of the finished product is within 0.5 mm. The regulation and precision of molds and equipment play a very important role in the product, which is why we invest a lot in this area.

curve edge fit

Right angle fit

Cylindrical edge fit

Packaging

Each product is a customized foam tray packed and is vacuum-sealed to ensure your product arrives qualified and safely.

PLA products are transported in a constant temperature container to ensure that the products will not be deformed or discolored under the condition of constant temperature.